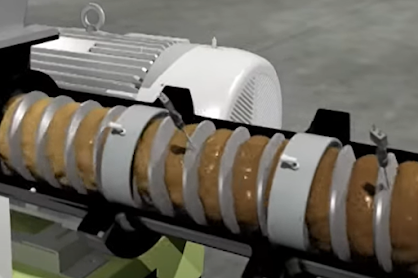

Extrusion, a process with ancient roots dating back to civilizations like Egypt and Mesopotamia, involves a screw within a cylindrical chamber. The credit for this foundational concept goes to Archimedes of Syracuse, a Greek mathematician and physicist who lived around 287–212 BC. Archimedes' inventive use of a screw within a wooden apparatus to elevate water from lower to higher levels was remarkable for its time.

This straightforward principle turned out to be pivotal across diverse industries, encompassing metals, ceramics, concrete, plastics, polymers, and even the production of food and feed.

Over the last couple of centuries, extrusion technology has undergone substantial transformation. Joseph Bramah acquired the initial extrusion patent in 1797 for crafting lead pipes via a ram-type machine and die. The technique, known as 'squirting,' eventually gave way to Thomas Burr's hydraulic press in 1820.

A pivotal advancement came in 1894 when Alexander Dick introduced the modern hot extrusion process, applicable to a wide range of non-ferrous alloys. The earliest documented extrusion apparatus featured a toothed rotor propelled by a winch within a toothed cylindrical cavity, primarily employed for rubber processing.

In 1820, Thomas Hancock developed a rubber masticator to repurpose rubber scraps, while Edwin Chaffee's creation of the first two-roll machine for rubber mixing in 1836 laid the groundwork for plastic extrusion devices, even though they weren't originally designed for that purpose.

In 1845, Richard Brooman and Henry Bewley patented the extrusion of Gutta Percha for copper conductor insulation. The inception of the extruder, a pivotal element in polymer processing, is linked to Mathew Gray's 1879 patent in England. Around the same time, Royle in the US also devised a screw machine.

The inaugural food extruder emerged during the 1870s for sausage production. In the 1930s, breakfast cereal manufacturing embraced extrusion to shape precooked dough, characterized by low shear rates. In 1933, the first continuous single-screw extruder with profiles conducive to low-temperature drying was introduced, supplanting batch systems.

In the late 1930s and 1940s, high-shear extruders facilitated the production of directly expanded corn curls. The inception of twin-screw extrusion technology was marked by the filing of the first patent in the mid-1950s.

While single-screw extruders found utility in the 1940s, twin-screw counterparts found their way into the food industry in the early 1980s and quickly gained popularity.

Evolution of Extrusion Technology

The history of food processing centers on the transformation of raw ingredients into food or various food forms. This tradition can be traced back to ancient times, specifically the prehistoric era, where early processing techniques like roasting, smoking, steaming, fermenting, sun drying, and preserving with salt were utilized. Without a doubt, food processing stands as one of humanity's oldest practices, dating back to time immemorial.

Pages

Saturday, August 19, 2023

Popular Posts

-

Food preservation is as old as human civilization. Preservation of foods inhibits spoilage cause by bacterial growth, oxidation, insects or...

-

The mechanization of tomato paste production traces back to the early 20th century, as industrial food processing evolved to meet rising urb...

-

Prior to the development of refrigeration and cooling technologies, large quantities of salt were added to meats for long term preservation....

-

During the 20th century the continued application of scientific research to food production has significantly changed the way the world eats...

-

The grain paste left to stand for a time sooner or later collects wild yeasts form air, and begins to ferment. This was the beginning of lea...